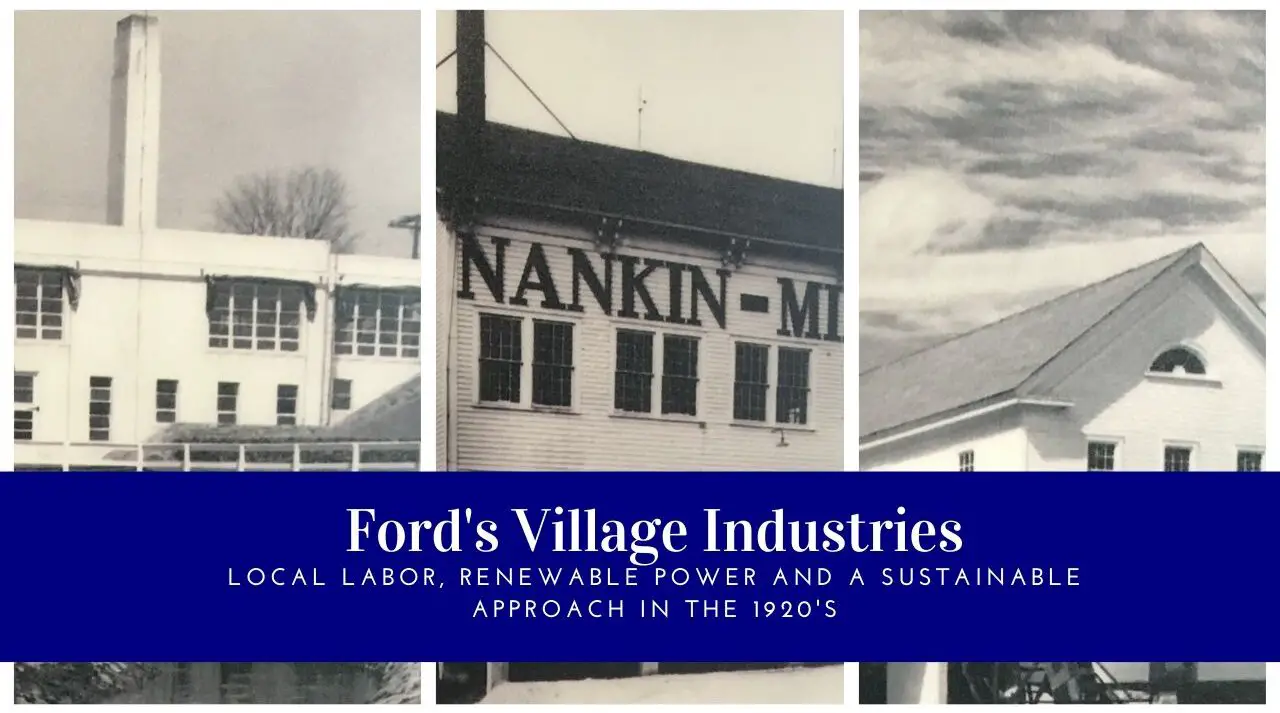

Henry Ford, the founder of Ford Motor, was increasingly concerned with cities’ unfettered growth. People streamed into Detroit and other industrial towns looking for work. The United States was changing from an agricultural to an industrial nation. Ford also wanted to stem poverty in rural areas for those with seasonal work. His solution; is Henry Ford’s Village Industries.

Village Industries

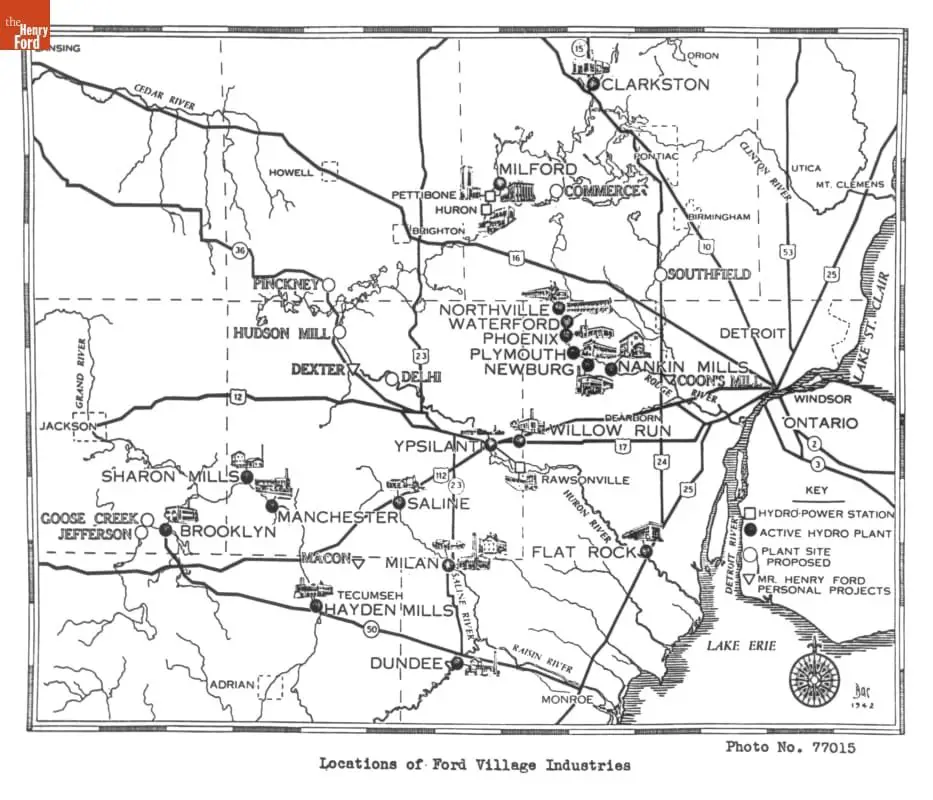

Map of Village Industries Locations

Henry Ford established a series of twenty village industries in southeast Michigan and other states where Ford Motor’s had a presence. He started acquiring and building small factories from 1919 until 1944, primarily in southeastern Michigan. Concerned about the availability and problems with using fossil fuels, Ford wanted all the plants to utilize water-powered turbines for electricity. Ford had a list of over 200 potential sites, with 75 located in Michigan.

The initial five plants consisted of grist mills and factories along the Middle Rouge River in the 1920s. Nine more were built in the 1930s and five in the 1940s. He targeted the Rouge, Huron, Raisin, Saline, and Clinton Rivers to utilize hydroelectric turbines.

All the village industry plants made automotive parts except for Macon. Macon was a gristmill built by Ford as a religious wheat tithing project. However, the mill was never opened.

During World War II all the plants were switched to wartime production. Three of the plants were involved in soybean extraction for the production of oils used in paint and plastics. Soybean production ceased in World War II.

The Village Industries joined four other outstate lumber operations in northern Michigan’s Upper Peninsula. Operations in Iron Mountain, L’anse, Alberta, and Pequaming all made products utilized by Ford Motor operations.

Village Industry Sites

This listing constitutes the small factories and operations in Southeast Michigan. They are the generally accepted list of facilities for the economic experiment.

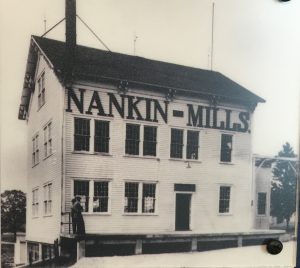

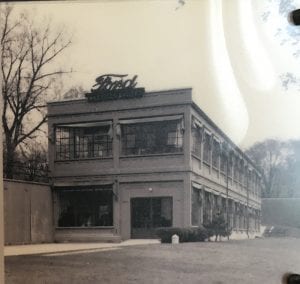

Nankin-Mills

This is the first location acquired for Henry Ford’s Village Industries Project. In 1918 Nankin Mills was a retired gristmill built in 1863. The original building was renovated by Ford and officially opened in 1921. The factory manufactured rivets, carbonator parts, and machine screws. In 1937 Ford retooled the Nankin site for stencil and engraving operations. This continued until 1948, when the operations were moved to Waterford. Clara Ford deeded the Nankin site to Wayne County, which operated a Nature Center from 1958 through 1979. It was reopened in 1997 as an Interpretive Center in 1997 and exhibits began in 2001.

Plymouth Tap Operations

Purchased in 1920, the site of the dilapidated Holbrook and Hardenbergh gristmill was originally constructed in 1845. A new building was put in place in 1923. Initially, generator cutouts were produced but that operation was soon moved to the Phoenix Plant. Plymouth became the source of 95% of the Ford Motor Company’s taps. Taps are used for forming internal screw threads. Plymouth tap operations were transferred to Waterford in 1948. Today the site is utilized by Wayne County for storage.

Macon Dynamic Kernels Mill

In 1944 Ford completed building a new Greek Revival gristmill, Dynamic Kernels Mill along the Raisin River in Lenawee County. Ford owned a home nearby in the old Pennington homestead which he restored. He also updated a chapel, general store, sawmill, school, fire department, blacksmith, woodworking, and community center. These building Ford built for a trade school in Macon are still used by Boysville today. Ford became interested in the religious wheat-tithing project being run by Quaker Perry Hayden. Ford built the Dynamic Kernels gristmill of the project however he abandoned it before it ever opened. Today the site is privately owned. The Macon Mill is a perfect example of the Village Industries’ water power being used.

Cherry Hill

In 1944 Ford relocated and rebuilt a dairy milk station to be used as a dormitory for workers. A new plant building was built at the site of the former village of Cherry Hill. The ignition, door lock, and key operations moved here from Willow Run, and door hinges were also manufactured here. This Village Industry served as a rehabilitation site for injured World War II veterans. Ford would not allow reporters to disturb the workers on this site to rehabilitate in privacy. Operations ended in 1945, and Cherry Hill served as a planning site for Village Industry consolidation in 1946. In 1950 it was sold and operated with several industries and today operates under De-Sta-Co since 1994.

Clarkston

The Clarkston Mill was demolished in 1917. Ford purchased the old mill site in 1920 and the Union School Building in Clarkston in 1940. He converted the schoolhouse into an apprentice school. Later the school building housed the library and currently the Independence Township Hall. Ford built a factory in 1942 near the old mill site, which was used for military production during its entire operation until 1946. Drills and bushings were made in the factory building, and straps and seat covers for government vehicles were produced in the schoolhouse. It was vacant for several years until the 1970s when converted to a “boutique” mall and restaurant.

Milan

Ford renovated the 1840s Greek Revival gristmill from Wilson’s mill/sawmill complex in 1936 and built a new hydro plant building, bridge, and dam. He also added a barn to the site from Highland Park because it utilized flow-through ventilation. Ford used it and the gristmill for soybean storage and processing from 1938 – 1946. He made plastic parts, ignition coils ammeters in a new brick hydro plant. Ford sold the buildings in 1948. Milan Department of Public Works had owned the brick hydro plant, and it now houses Milan City Hall and Public Library.

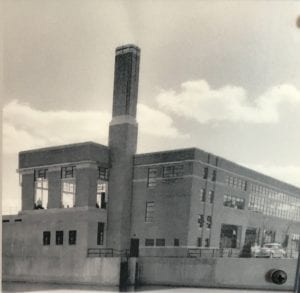

Phoenix Plant

In 1920 Ford purchased an 1840s Phoenix gristmill and Matthews Distillery, which had burned down in 1905. Ford constructed a new building in 1922 beside the beautiful millpond of Phoenix Lake. The Phoenix plant was unique in that it employed mostly women. Ford felt that women were more adept at assembling delicate electrical parts such as voltage meters, light switches, and generator cutouts. Since 1948, when operations transferred to Ypsilanti, and Clara Ford deeded the site to Wayne County, it has been a maintenance facility and serves as the Road Commission sign shop. Phoenix lake was a popular swimming beach until it closed in 1933.

Northville

Located on the site of an 1820s lumber mill and gristmill, Ford purchased the Dubuar lumber mill and furniture plant in 1919. He began producing valves in the original building in 1920, then constructed a new building in 1936. Ford operations ended in 1981 but resumed in 1983 – 1989 when the site was used for building fuel tanks. The building served as a community center for Northville after Ford operations closed. Currently, R&D Enterprises makes boat parts and leases out offices to several other businesses.

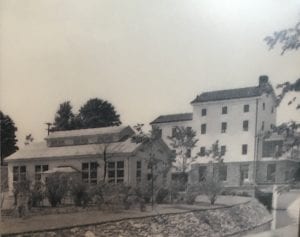

Tecumseh – Michigan Hayden Mills Hydroelectric Plant

The original 1835 Globe Mill built by Stillman Blanchard was sold in 1858 to William Hayden, who operated a gristmill burned down in 1898 and was rebuilt. Ford purchased the property in 1935, removed the mill, and rebuilt it that same year to resemble the mill’s Dutch Colonial architecture, using the original foundation. Soybeans grown on area farms were processed here to manufacture plastics and paints for Ford automobiles. Ford operations ceased in 1948, and the building was used for storage until it was sold in 1951. Several business ventures used it and now serve as a community center for the village of Tecumseh.

Dundee

Early mills at this site included the 1827 Ingersoll/Gale Sawmill and the 1832 VanNest gristmill. Dundee Hydroelectric Power Company owned the site in 1910, then Detroit Edison in 1920. In 1931 Ford bought and refurbished the 1866 Alfred Wilkerson Greek Revival gristmill, adding a new stone section in 1936. Copper welding tips were made using scrap copper from the Ypsilanti plant. Brass and bronze parts were cast as well. In 1954, Ford operations ceased, and Wolverine Manufacturing and Fabrication began producing gaskets here. Dundee’s village acquired the site in 1970 and restored the building in 1981 as the “Old Mill Museum,” council chambers, and community center opened in 1986.

Flat Rock

Two new buildings were constructed in 1923 on the site of the former Melter and Dickman gristmill that Henry Ford had purchased in 1921: a water filtration plant and a lamp factory. Ford manufactured head, tail, and interior automobile lamps. He also operated a flax mill behind the plant for three years to make fiber for upholstery. After the Ford operations ceased in 1951, the village of Flat Rock owned the water filtration plant, and the village’s offices were moved in. It is now a senior citizen’s center. The lamp factory changed hands to Federal Engraving, the parent company of Moynahan Bronze, and Sterns manufacturing. Initially, Moynahan Bronze made precision airplanes parts at the old lamp plant, and in 1964, Sterns moved in as well, manufacturing concrete block-making equipment and conveyor belts.

Brooklyn

In 1939 Ford built a new factory on the site of the Swan sawmill built-in 1832. The Mill crushed cider, and the Tiffany gristmill (later known as Brooklynn Mills burned down in 1912). Horns, starter switches, and distributors were manufactured here until 1954 when these operations transferred to Ypsilanti. Brooklyn then converted to a plastics plant, making lamp lenses and armrests. Ford operations continued at the site until 1967 when the plastics operations moved to the new Saline Plastics plant. After being used by Jackson Gear Company for twenty years (1969-1989), the building was purchased by Leo Koepke in 1990. Today his company, Yesteryear Power and Equipment, still owns the building. He has restored the generator, which heats part of the building, and is planning to open as a museum in the future.

Milford

The Milford site was the home to many mills: the 1836 Phelps sawmill and distillery, an 1845 gristmill, planning mill, and woolen mill. In 1938, Ford built a new factory, dams, and two powerhouses. The Huron River powerhouse, which has since been torn down, was built on the old Milford Electric Company hydoplant. Ford built the second Pettibone powerhouse, where no former hydropower facility had been. Ford manufactured carburetors here until 1947, and the buildings were sold in 1957. In 1970 the Pettibone powerhouse became a canoe livery, owned by the Village of Milford

Manchester

Ford built a new factory in 1941 on the site of the 1833 Soule sawmill and Premium gristmill. Ammeters, Dashboard gauges, and interments were manufactured at this Henry Ford Village Industry site. Soybean-based plastics were used to make parts of the gauges. Operations were transferred to Ypsilanti in 1957. By 1961, Thornton Tandem Four-Wheel Drive owned the building. Today the Village of Manchester owns the building, which is located on the Raisin River in Washtenaw County

Newburgh

Ford constructed a new building in 1935 at the site of the old Newberg cider and gristmill which he purchased in 1933. The workers who built the plant included employees of the Rouge plant and local farmers. They were hired as the first employees of this new Henry Ford’s Village Industries, specializing in the production of twist drills and drill bits. Clara Ford sold this building to the Wayne County Road Commission for $1.00 in 1948, and their Forest Division used the building until the 1970s. It now houses the Wayne County Sheriff’s mounted division.

Saline

Purchasing this site in 1937, Henry Ford disassembled and rebuilt the original 1845 Schuyler gristmill, board by board in 1938. He also constructed a new building that resembled the site’s original. Ford used the site for soybean processing until 1946. He purchased soybeans from over 700 local farmers and produced oil for paint and plastics for his automobiles. Valley Chemical Company purchased the building in 1947 and continued to process soybeans. The site is on the Saline River in Washtenaw County.

Sharon Mills

Purchased in 1927, it wasn’t until 1939 that Henry Ford renovated the oldest and smallest Village Industry building, the 1834 stone and timber Kirkwood gristmill, insisting on hand-hewn beams and wooden pegs. He added a fieldstone addition, a new dam, and a bridge. Dome light and stop light switches were manufactured as well as cigar lighters. Henry Ford condemned cigarettes, so the lighters in his cars were called cigar lighters. Ford operated at the site from 1939 to 1946 and was sold in 1951. The mill was recently sold to Washtenaw County Parks, and they are planning to develop it as an Interpretive building. The site is located near the Raison River in Washtenaw County in Sharon Hollow, keeping with the Village Industries water power concept.

Waterford

Ford built a new building in 1925 in the historic town of Waterford on the site of the old Mead’s gristmill, which had burned down in 1865. Skilled artisans manufactured Johansson high precision gauge blocks (Jo Blocks) from 1925 – 1954. In 1948, an annex was added to consolidate the Plymouth, Nankin, and Newburgh operations in Waterford. Ford sold the Waterford plan in 1957.

Willow Run Lock and Key

Ford initially operated Camp Willow Run on this site for one season in 1940, which provided farm employment for underprivileged boys. Ford built a new factory in 1941, and the most qualified boys from the camp were employed at this Village Industry, making ignition and door locks and plating keys. The foundry at the plant used 1000 pounds of metal to produce 2000 locks a day. The little factory was torn down in 1944 to make room for the Willow Run B-24 Bomber Plan, the first and only Village Industry building to be dismantled. The lock and key operations moved to Cherry Hill.

Ypsilanti Starters and Generators

Ford constructed a new building and powerhouse in 1932 near the historic village of Rawsonville. The power of the Huron River was used to operate a sawmill and gristmill at this site. Under Ford’s operation, starters and generators were manufactured by Ford at the Ypsilanti plant. Later, Henry Ford’s Village Industries building was absorbed into the larger Rawsonville facility on the site. Today, Visteon, near the old millpond, is the current occupant.

Sources of Information for Ford’s Village Industries

- Featured Photo From the Collections of The Henry Ford. Gift of Ford Motor Company.

- Nankin-Mills Interpretive Center

- The Henry Ford Museum

Related Reading

- Interesting Films Made in Michigan

- Wind Energy Development Transforms Michigan’s Thumb

- Kinde Michigan – Our Beantown

- White Rock: The Sacred Cornerstone of Michigan’s Thumb

- Local Brewing is Sustainable

- Ora et Labora Experiment by Florence Gwinn

Discover more from Thumbwind

Subscribe to get the latest posts sent to your email.

Just a FYI. Willow Run Lock and Key did NOT get torn down in 1944. It simply stopped operating after the war ended. It had switched over from producing locks to drilling out certain bomber parts when the camp shut down. Kaiser Frazer never operated the small plant with it’s hydro and steam power capabilities. GM tore the top level of the Willow Run lock and key plant down sometime around 1959. The windows and doors were covered over with cinder blocks and it sat and still sits in sad condition thru out the years of wind, weather and vandalism. It is now surrounded by fencing as it is in the center of the new Michigan Center for Mobility off road test track. It is maintained by Washtenaw County.